I. Overview:

There is a Fujian company producing maintenance-free valve-controlled lead-acid batteries. Its production workshop was provided with multiple large-power devices with nonlinear loads like rectifying charge-discharge device. Hence during operation, a great amount of current harmonics were generated and turned into harmonic voltages by system impedance. The injection of the considerable quantity of harmonics into the point of common coupling (PCC) contaminated the power supply system, affecting the stability of production equipment in long-term operation. Therefore, it was essential to suppress the system harmonics so that the power quality and the operation security of the equipment might be secured.

II. Hazards of harmonics

1. When the harmonic currents and voltages injected into the PCC are in excess of the limits specified in GB/T 14549-93 Quality of Electric Energy Supply: Harmonics in Public Supply Network, the public grid will be contaminated.

2. Both the power supply and consuming equipment will not be fully functioning, giving rise to a waste of resources.

3. The input of a traditional capacitor set will generate parallel resonance with the system, severely jeopardizing operation safety of the system.

4. The capacitor sets will suffer from frequent damage or switching malfunctions when running with overcurrent or overvoltage under strong harmonics.

5. Leading to excessive temperature rise of transformers and aggravating both the active and reactive power loss, increasing the cost of power consumption of enterprises.

6. Interfering with the meters of electricity selling points, causing severe measurement errors.

7. The production and long-term stability of power supply equipment will be affected. It has been proved that the effective solution to the problems mentioned above is installing a harmonic filter at the LV side of the main transformer, and hence this suppression plan is hereby prepared.

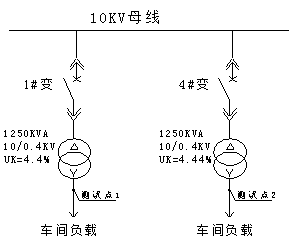

III. Introduction to power supply system

IV. Targets of suppression

Both the current and voltage harmonics injected into the PCC are in compliance with GB/T14549-93 Quality of Electric Energy Supply: Harmonics in Public Supply Network, and fulfill the requirements of normal operation of power supply and production equipment.

V. Elimination methods for harmonics:

в—Ҹ Using TSF (Thyristor Switched Filter) to implement fast, dynamic response compensation;

в—Ҹ Employing passive filtering to filter a considerable amount of current harmonics, thus reducing the harmonic voltage;

в—Ҹ Installing a set of WXL-A filter for the 0.4 kV side of the power supply transformer;

в—Ҹ Excluding the existing capacitance compensators from operation.

VI. Design of filtering compensator:

6.1: Technical indicators of TSF filtering compensator

6.1.1 The filtering compensation system is connected to the secondary side of the rectifier transformer.

6.1.2 The absorption rate for 5th, 7th and 11th harmonic currents shall reach over 75%, and the harmonic voltages of the corresponding sequences shall conform to GB/T14549-93.

6.1.3 Response time вүӨ 20 mS.

6.1.4 Voltage fluctuations in the grid during compensation comply with GB/T14549-93, i.e. the voltage fluctuation of the primary side as a result of variation from full to light load compensation вүӨ 2.5%.

6.1.5 The compensation system is provided with the following operation security measures:

System: overvoltage, overcurrent, undervoltage and grounding protection.

Capacitor: overvoltage, overcurrent and overheating protection.

6.1.6 Total power consumption of compensation system: Ploss is smaller than 1.5% * Qtotal (where Qtotal is the total compensation).

6.1.7 The system generates no radio (radio frequency) EMI.

6.1.8 Operation modes: Fully automatic, operating continuously.

6.1.9 Displaying 11 kinds of data like Parameter, PF, U, I, S, Q, P and Working order.

6.2: Determination of filtering compensation branches:

1. Computing formula: Q = P (

)

)

Where, Q - compensation capacity

P - load power

CosС„1 - power factor prior to compensation

CosС„2 - target power factor after compensation

In consideration of site conditions and the past experience on suppression (e.g. suppression projects of Yuasa Battery and Lingyun Storage Battery),

a certain margin of 670 KVAr is provided.

2. Determination of filtering and compensation loops

Through establishment of the abovementioned known and reckoned parameters, the harmonic compensation system is determined. And by amending the analog results for a couple of times, all loop parameters can be defined.

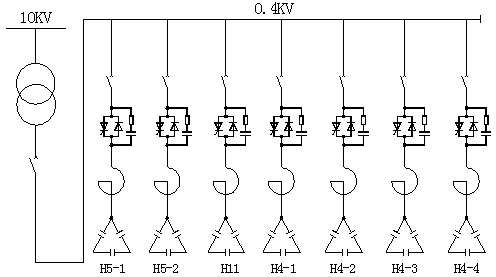

H5-1 1 filtering compensation branch 180 KVAr of fundamental compensation capacity

H5-2 1 filtering compensation branch 180 KVAr of fundamental compensation capacity

H11 1 filtering compensation branch 90 KVAr of fundamental compensation capacity

H4-1 1 filtering compensation branch 60 KVAr of fundamental compensation capacity

H4-2 1 filtering compensation branch 60 KVAr of fundamental compensation capacity

H4-3 1 filtering compensation branch 60 KVAr of fundamental compensation capacity

H4-4 1 filtering compensation branch 40 KVAr of fundamental compensation capacity

VII. Primary circuit diagram:

VIII. External dimensions:

1. The cabinet assembly of Transformer 1# (1,250 kVA transformer) comprises of a total of 3 cabinets:

Size of each cabinet: 1,000 (W) Г—1,000 (D) Г— 2,200 (H)

2. The cabinet assembly of Transformer 4# (1,250 kVA transformer) comprises of a total of 3 cabinets:

Size of each cabinet: 1,000 (W) Г—1,000 (D) Г— 2,200 (H)

IX. Requirements on element selection:

1. Selection basis and protective measures of filter capacitor

All-film capacitors, with the capacitor film special for compensation and filtering manufactured by the French company BOLLORE, shall be employed for filtering. The requirements are as follows:

(1) The line current density is 0.12 A/m or equivalent to the capacity of 1 kvar (0.45 kV); max. allowable current, 2 Ar.m.s; ability to withstand short-circuit impact current, 60 A; ambient temperature for use, -25В°C - +55В°C; temperature coefficient, 0.015%; and in the standard ambient temperature of 20В°C, the capacity variation from -20 - +55В°C is no greater than Вұ0.006;

(2) Capacity loss less than 0.001 (tgОҙ);

(3) Annual decay rate of capacity is no greater than 0.02%;

(4) Provided with overvoltage protection: the capacitor will not break down upon overvoltage, and will automatically release the energy of the transient overvoltage;

(5) Provided with overcurrent protection: when the current exceeds the allowable values, the internal pressure safety device will cut off the power source;

(6) Overheating protection: same as overcurrent protection;

2. Selection basis and protective measures of filter reactor (inductor)

(1) Good linearity, using orientation silicon wafer and appropriate air gap;

(2) Employing conversion technology and vacuum impregnation;

(3) Provided with temperature protection with the threshold of 105В°C (coil);

(4) Operation noise level of individual reactor < 45db under power frequency and < 55 db under harmonic environment.

3. Selection of thyristor

The national product manufactured by the Semi-Conductor Plant of CRRC Zhuzhou Institute - KPA, voltage resistance 3,800 V, average on-state current 2,000 A, 3,000 A.

4. Selection of compensation controller

Using the CY-JK200 self-adaptive reactive power compensation controller.

(1) Response time вүӨ 20 ms; drive level 0 - 12 V;

(2) Drive ability 200 mA Г— 12;

(3) Self-adaptive function, one-button function;

(4) Provided with phase loss, overvoltage, and undervoltage protection; and

(5) With strong harmonic resistance, operational under environments of great harmonics and impact loads.