Harmonic control for intermediate frequency furnace in smelting industry

I. Overview:

Intermediate frequency smelting furnace has been widely used in smelting, casting and such industries increasingly. However, this kind of furnace adopts rectification and inverter technology during work and produces a large quantity of current and voltage harmonics. Harmonics will give rise to serious pollution of power supply system and misoperation of precise instruments during work, and thus, increase loss of power supply equipment. Through on-site data collection and analysis, we have produced the passive power filter (TSF) researched and developed by ourselves.

II. Solution

1. Filter compensation control

Thyristor Switched Filter (TSF) is used and system equipment conducts rapid dynamic response for compensation.

2. Main technical indexes of TSf:

2.1пјҡFilter is connected to the secondary side of transformer.

2.2: Filtering system adopts thyristor switching and can achieve dynamic tracking of load change, with the response time вүҘ20ms.

2.3: Zero-crossing triggering technology is adopted. Switching can be done without inrush current, shock, switching over-voltage and discharge.

2.4: Absorption factor of harmonics: For 5th, 7th and 11th harmonic current, absorption factor exceeds 75%.

2.5: Under special circumstances when power factor of intermediate frequency furnace is very high, the furnace with the average power factor of 0.80 before compensating shall be such compensated that power factor should exceed 0.95, on the premise of no excessive compensation (i.e. lead compensation).

2.6: In the process of compensation, fluctuation of network voltage shall comply with national standard GB/12326-90, that is: voltage fluctuation at primary side arising from change from full load to light load compensation shall be вүӨ2.5%.

2.7: Filter compensation system has the following measures for safe operation:

System: Over-voltage, over-current, low-voltage and ground protection

Capacitor: Over-voltage, over-current, overheat and out-of-phase protection;

Inductance (Reactance): Over-current and overheat protection

2.8: Total power loss of filter compensation device: Ploss is less than 1.5% * Qtotal (Qtotal refers to the total compensation)

2.9: The system will not produce radio (radio frequency) electromagnetic interference.

2.10: Operation mode: Full-automatic and continuous operation.

Display parameters: 11 kinds of data like PF, U, I, S, Q, P and working order.

3.3 Schematic diagram of filtering

III. Effects of control:

After putting filter into service, power quality of the CompanyвҖҷs power supply system has been improved remarkably, both current and voltage harmonics can comply with GB/T 14549-93.

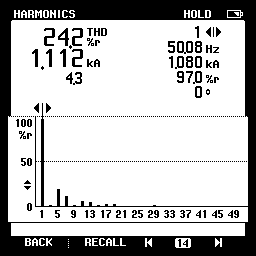

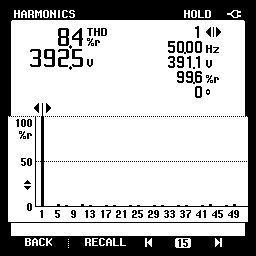

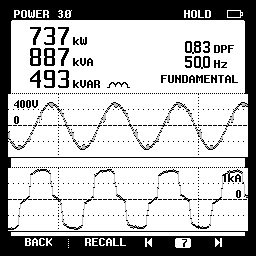

Before operation of filter

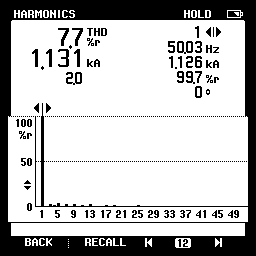

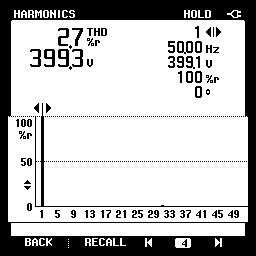

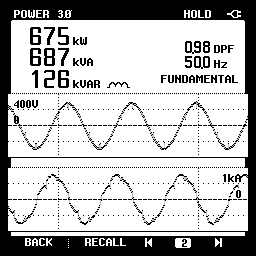

After operation of filter

V. Summary:

1. Thyristor Switched Filter (TSF) is used and it can achieve rapid and automatic tracking of the entire smelting process of intermediate frequency furnace, so as to removing all orders of harmonics in an efficient manner.

2. After putting filter into service, it can relieve current shock arising from impact load, decrease voltage fluctuation, suppress voltage flicker, increase voltage stability and improve power quality.

3. In addition, loss of the userвҖҷs line and power supply equipment can be decreased and working efficiency in workshops and offices can be improved, with remarkable economic benefits.